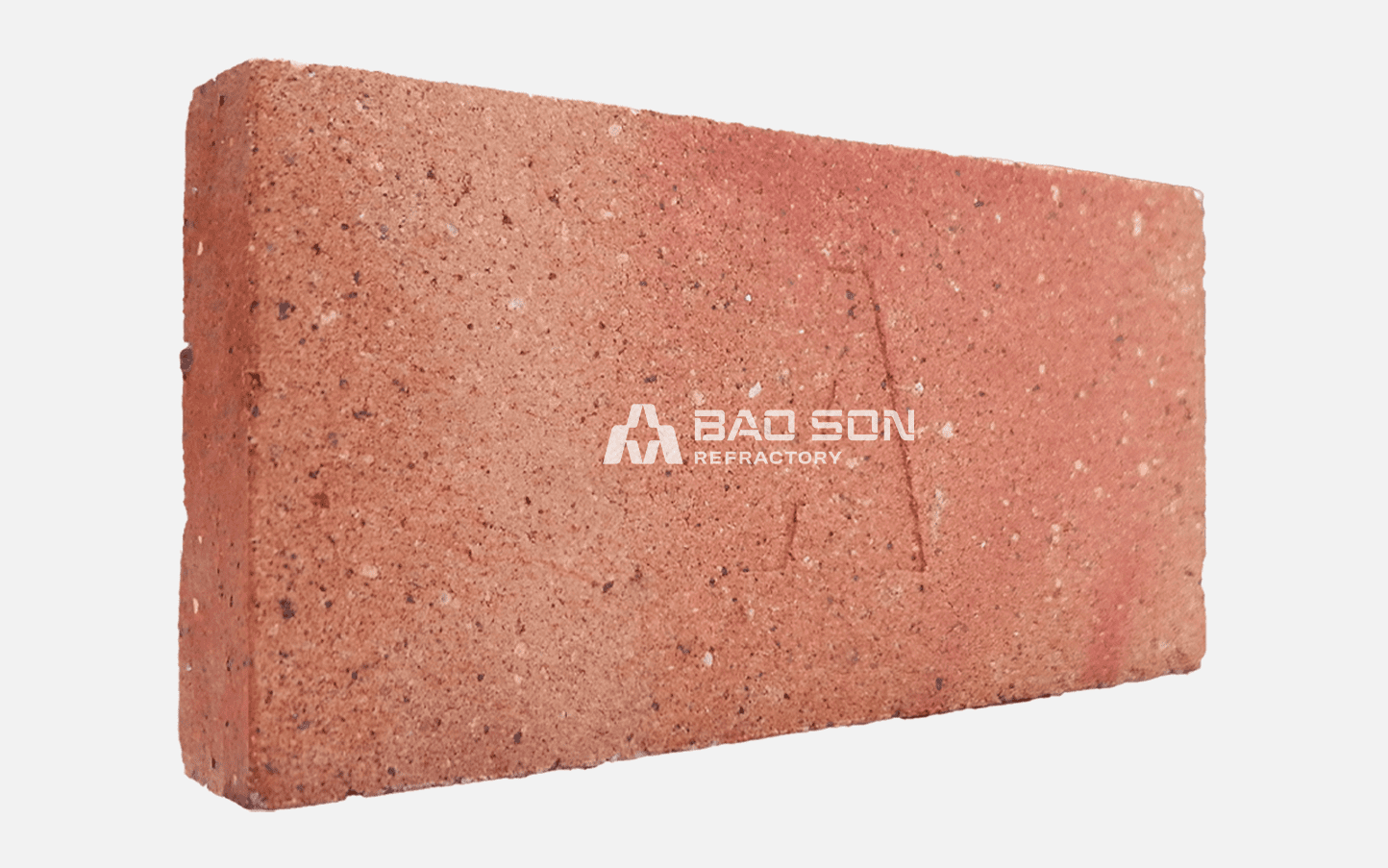

Fire brick – An outstanding solution for heat-resistant constructions. With advanced production technology, Fire brick provided by Bao Son company meet high quality standards

Outstanding advantages

-

01

High durability, low thermal conductivity and high thermal shock resistance, heat resistance up to 1580°C

-

02

Reduce energy costs, and equipment damage caused by external factors, increasing the life of auxiliary equipment and devices

-

03

Save fuel due to reduced heat loss and heating of furnace walls

Choose heat-resistant bricks when building furnace walls

Choose heat-resistant bricks when building furnace walls

In industrial incinerators, fire resistance and heat resistance are indispensable factors to ensure the safety and performance of buildings operating at high temperatures. It is then that fire bricks of different shapes become important. Not only does it guarantee strong fire resistance, but it also demonstrates a variety of application features and outstanding advantages, from industrial incinerators to furnaces and boilers.

Learn about the different specifications of Heat Resistant Bricks

Knife-beveled bricks and hammer-beveled bricks are heat-resistant and fire bricks with special shapes designed for use in applications that require outstanding durability and heat resistance, such as kilns and kilns. incinerators, boilers, industrial furnaces, and high-temperature working environments. All these types of bricks are manufactured from refractory materials such as minerals, fire retardants and heat-resistant compounds.

With a special shape that is slightly curved like a shoulder, or like a hammer or knife, these bricks are designed to be built in furnaces with many shaped structures. These structures are mentioned as the roof of the Z furnace of the toilet, the feed door, the ash rake door, the air intake, etc., and have different shapes, because they use bricks of different shapes to process them. thoroughly.

Structure and composition of heat-resistant bricks

Structure

The structure of each type of brick also affects its properties. Knife-beveled and hammer-beveled tiles often have a curved shape to help optimize heat dissipation and heat resistance. Knife bricks and hammer bricks have special shapes, helping to increase load-bearing capacity and fire resistance. The locations of the door and the air ducts entering the combustion chamber are the places that need to have the strongest structure because these places are the most susceptible to damage. Normally, boiler manufacturers often use arched structures made of arched bricks, hammer-beveled bricks, and knife-beveled bricks.

Material composition

The structure and material composition of shoulder bricks, knife bricks, and hammer bricks are the decisive factors for their heat resistance, fire resistance, and performance in high temperature environments. These types of bricks are often produced from special materials to ensure heat resistance and fire resistance.

The material composition of heat-resistant bricks often includes heat-resistant minerals such as lime minerals, alumina, gypsum minerals, and silica minerals. These components create the refractory structure of bricks, helping them maintain stability under the influence of high temperatures.

Diverse types of fire bricks

Rectangular heat-resistant bricks: Dimensions 230x114x65mm, heat resistant up to 1530°C. Often used in building foundations, walls and furnace walls.

Knife and hammer shaped heat-resistant bricks : Shaped with a horizontal bevel (knife) or vertical bevel (hammer), size 230x114x65/55mm or 230x114x65/45mm. They are often used in dome construction, screw feed mouths, air supply mouths, door positions or locations that require curvature.

Types of heat-resistant bricks: In addition to the above types, there are also many other shapes and specifications according to customer requirements, including thin bricks, 5-inch bricks, 7-inch bricks, 8-inch thick bricks, beveled bricks, hammered bricks. , and many others.

Learn more about : Heat-resistant bricks at Bao Son

Application of fire bricks

Heat-resistant bricks are widely used in many industries, including:

Metallurgical industry: Construction of metallurgical furnaces, glass furnaces, trash incinerators and many other applications.

Cast iron production : Used in the construction of blast furnaces, hot wind furnaces, cast iron dumping tanks and related applications.

Steel industry: Construction of steel water tanks, billet casting, billet furnaces and many other jobs.

In addition to being resistant to high temperatures, heat-resistant bricks are also resistant to scratches upon impact, are waterproof and prevent the appearance of moss and mold.

Learn more about : Application of heat-resistant bricks at construction sites

How to build furnace walls and kilns with heat-resistant bricks?

Furnace walls are of two types: straight and curved. For straight walls, we build them with regular heat-resistant bricks. For curved walls, we use all heat-resistant bricks with standard sizes or flat beveled bricks such as knife bricks, hammer bricks, knife beveled bricks, hammer beveled bricks. During the construction process, make sure to stagger the circuits between rows. Change the position of the bricks by alternating rows arranged along the furnace wall with rows arranged perpendicular to the furnace wall.

The walls of the kilns are built vertically. For smelting furnaces, to increase durability and improve the distribution of gas and material flows, people often build them at an angle with the wall thickness decreasing with height.

The wall is built in 2-3 layers: The innermost working layer is built with appropriate heat-resistant bricks, with the necessary thermal and mechanical durability. The outermost layer is insulation. When the kiln wall consists of many layers of bricks, build one type of brick in each layer. To ensure a solid connection between the inner layer and the outer layer, from a height of 2.5 – 3 m, after every 5-6 rows of bricks in the inner layer, one half of the bricks are divided into the outer layer.

The thickness of the furnace wall can be from 0.4 to 1.6m depending on the nature of the furnace technology. The thickness of the heat-resistant brick layer must be over 230mm. The thickness of the insulation brick layer is from 115 to 350 mm. If it is powder or fiber insulation, it only needs 30 to 100 mm. While building the furnace wall, knife bricks, hammer bricks or other bricks are all built horizontally.

Advantages of fire bricks in industry:

High durability, low thermal conductivity and high thermal shock resistance, heat resistance up to 1580°C

Reduce energy costs, and reduce equipment damage caused by external factors, increasing the life of auxiliary equipment and devices

Save fuel due to reduced heat loss and heating of furnace walls

How to choose the right heat-resistant bricks

When entering into the construction of projects that require heat resistance, choosing the appropriate heat-resistant brick is a factor that cannot be ignored. This process requires careful consideration of operating temperatures, environmental impacts, and specific technical requirements.

Shoulder bricks, knife bricks, and hammer bricks have different levels of heat resistance. The shape and structure of each type of brick also affects their heat dissipation and heat resistance and each construction location is different. For example, in the position of the furnace roof or the dome of the furnace door, hammer bricks are used because they have a shape suitable for that position.

Surveying the working environment is also important. Factors such as chemicals, humidity, pressure, and other environmental agents can affect the properties of refractory bricks.

Finally, do not ignore the technical requirements of the project. Consider structure, location, and coordination with other components in the building. This helps ensure the safety and effectiveness of using heat-resistant bricks such as knife bricks, shoulder bricks, hammer bricks, etc.

In the boiler, the construction of the boiler combustion chamber is built by Bao Son Industry Co., Ltd. There are special shaped bricks that we are using such as: Knife shoulder bricks, hammer shoulder bricks, skirting bricks, high hanging bricks. aluminum, etc.

A reputable supplier of heat-resistant bricks

In general, fire bricks are the perfect solution for industrial applications that require good heat resistance and insulation. For important projects such as metallurgical furnaces, glass furnaces, or steel rolling furnaces, the quality and performance of construction materials are indispensable factors. Heat-resistant bricks not only meet these requirements but also help save fuel and protect the environment.

Bao Son Industry Co., Ltd. specializes in manufacturing and trading refractory, heat-resistant, heat-insulating, and sound-insulating materials for heavy industry, metallurgy, textiles, chemicals, cement, iron and steel. In addition, Bao Son Refractory also provides optimal heat insulation, heat insulation, sound insulation, and highly effective sound absorption solutions for factory, civil, and industrial park projects, and is a reliable and reputable address. , quality and speed for architects, investors and contractors nationwide

Please call us immediately for the best service: Hotline: 0949.413.503 Email: info.baosonnrf@gmail.com Website: baosonrefractory.com Address: 98, Hanoi Highway, Long Binh Tan Ward, Bien City Hoa, Dong Nai Province

See more: What is thermal insulation brick?

See more: Price quote for heat-resistant concrete

See more: Where to buy heat-resistant cement?